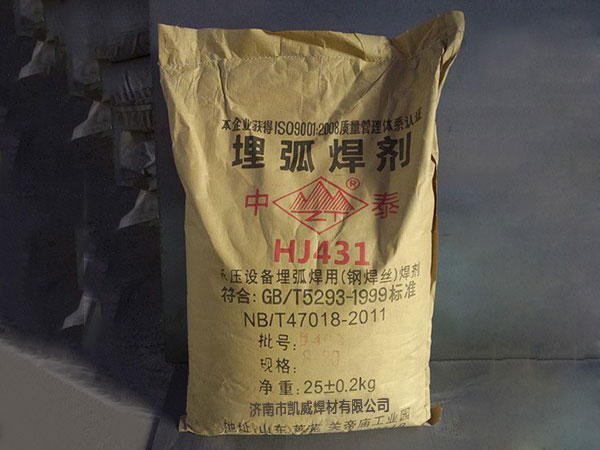

How much do you know about welding Flux?Welding flux is a granular welding material, which can be melted into slag and gas during welding, which protects the molten pool and plays a role of metallurgy.

There are three types of flux: neutral, acidic and alkaline. According to its manufacturing method, it can be divided into two types: smelting flux and sintering flux. There are many applications of acidic smelting flux for welding materials. It is equipped with suitable welding wires and is suitable for welding low-alloy structural steel and carbon steel. Alkali and neutral smelting fluxes are mainly used for welding high strength high strength steels.

Sintered flux refers to a very good, efficient, energy-saving and environmentally friendly flux. It refers to processing the prepared wet material flux into required particles, and calcining it at a high temperature of 750-1000 ° C to form fine particles to obtain a sintered flux. The flux is smokeless, odorless, arc-free, and spatter-free during welding.

The flux is made of chemical substances such as quartz, marble, fluorite, titanium dioxide, cellulose, etc. It is mainly used in electroslag welding and submerged arc welding. It needs to be used with the corresponding welding wire to achieve a satisfactory weld.

| Previous:How to choose a good quality flux? | next:Not only will flux be used, it will also need to be managed! |